Storopack’s FOAMplus® BAGPACKER is a foam-in-bag system that saves time and money by providing economical, efficient and secure protection for products of virtually any size, shape or weight.

Fast, Easy, Efficient Foam-In-Bag Packaging System

- Produces 23 foam-filled bags per minute at the touch of a button.

- Operator can easily change bag sizes and foam-fill amounts based on the packaging requirements.

- Easy-to-use programmable controller cuts waste, improves efficiency and simplifies operator training.

- Store settings for up to six different bag sizes with varying degrees of foam-fill amounts.

- Self-cleaning gun and robust design keep maintenance costs down.

Simple Steps To Free-forming Around The Product

STEP 1 Operator chooses the correct

pre-programmed bag length that will carefully meter a certain amount of foam. The pre-formed bag and foam are quickly dispensed.

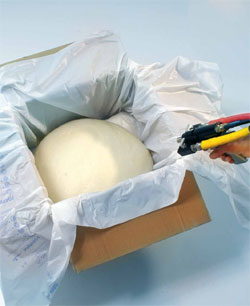

STEP 2 The bag is immediately placed in the box and the product lowered into the expanding foam.

STEP 3 A second pre-filled bag is placed on top and allowed to expand around the top of the product.

STEP 4 Seconds later FOAMplus® has created a clean, protective pad of foam that envelopes the product.

Simple Steps To Pre-forming Using A Mold

STEP 1

Operator chooses the correct pre-programmed bag length that will carefully meter a certain amount of foam. The pre-formed bag and foam are quickly dispensed.

STEP 2

The bag filled with FOAMplus® is placed in a mold designed to match the product.

STEP 3

The lid is closed and secured to allow the FOAMplus® to expand inside the mold creating a mirror image of the product.

STEP 4

A few seconds later a pre-formed protective cushion is ready for immediate use.

BAGPACKER

Size:59″ x 79″ x 29.5″

Weight:770 Ibs

Power:220 V – 30 amps

Speed:23 bags per minute

Practical and simple: The controls

The FOAMplus® Bagpacker controller is simple to operate and offers maximum flexibility. Easily program and store up to 594 settings for varying bag sizes and foam-fill amounts.

Safe and sound protection your products

FOAMplus® ensures that your customer receives an undamaged product in clean, professional packaging.

FOAMplus® adapts perfectly: Whether you use the hand-held or foam-filled bag system, you can always be confident that FOAMplus® will mold around the product, protecting it like a glove.

FOAMplus® is versatile: A wide selection of foam densities allows you to use FOAMplus to package any type of product.

FOAMplus® offers outstanding protection: The foam sets to an impact-resistant cushion, holding the product securely and keeping it safe.

FOAMplus® saves space: Foam cushions are produced as needed and the systems are extremely compact, giving you maximum yield while using minimal space. A unit with two 55 gallon drums can produce up to 3,200 cubic feet of protective foam cushioning.

FOAMplus® keeps transportation costs down: FOAMplus® provides superior protection and is very light weight.

The pulse of the packaging community